|

SVM-1VMC Workstation is a professional PC control based Mini Vertical Milling CNC. It’s smaller than SVM-2 but all made as standard industrial level VMC. It's equipped with standard industrial AC SERVO driving BT30 spindle, full linear ways and full AC SERVO 3 axis motion system that normally only be seen on big industrial CNC machines.

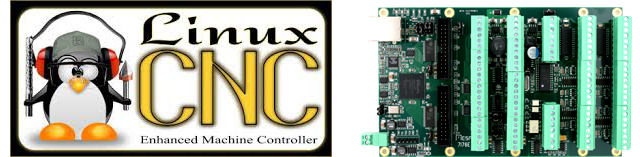

SVM-1VMC Workstation comes with Linuxcnc + MESA 7i76e CNC controller installed on a 14" touch panel tablet industrial computer. Linuxcnc&MESA system is professional and powerful under closed loop control to support SERVO, ATC, 4/5 axis and rigid tapping etc. high class functions that can compete most industrial CNC controllers.

SVM-1VMC Workstation can handle all materials from Plastic, Aluminium, Brass, Steel, Stainless Steel to Taitanium etc. It's a real industrial level CNC machine to do precision machining works. Typical machining tolerance is <0.02mm.

SVM-1VMC Workstation is excellent for personal machinists, metal workshops, R&D departments, educations and batch product factories.

KEY FEATURES

High rigid cast iron machine frame

Over 250kgs aging-treated cast iron frame to prevent losing accuracy by time |

|

|

Full linear ways and C3 class ground ballscrews for all 3 axis

HIWIN™ High precision class linear ways and C3 class ground ballscrews for all 3 axis / Z axis enhanced with heavy duty roller type linear ways

|

|

|

AC SERVO driving BT30 spindle system with Pneumatic PDB

Industrial precision BT30 spindle unit / High end AC SERVO spindle motor system

|

|

AC SERVO 3 axis driving system

AC SERVO motor system for all 3 axis / Run faster, more smoothly and never lose step |

|

|

Linuxcnc+MESA+touch screen PC based CNC control system

Front industrial touch screen tablet computer / Keyboard attached / MESA controller with Ethernet port

|

|

|

Full enclosure and integrated coolant&chip removing system

Industrial style full enclosure / Chip drand coolant system built in cabinet stand / Easy moving FOOT MASTER casters

|

|

|

2nd High speed engraving spindle (optional)

Special optional 2nd engraving spindle for precision 3D engraving works

|

|

|

Harmonic drive 4th/5th axis system (optional)

High accuracy, Zero backlash 4th/5th axis set attachable

|

|

|

BT30-ATC-8T is now available on SVM-1 (optional)

SKYFIRE own developped BT30-8T ATC system / Less weight, full linear ways, optimized for small CNC

|

|

Various optional installations, upgrades, tooling and accessories (Please refer to datasheet)

MPG, tool setters, BT30 tool holder series, machine tools etc.

|

|

QUALITY CONTROL

All SKYFIRE CNC machines will be tested on motion accuracy and kept running over 72 hours after assembly.

REAL CUT TESTS

All machines will be applied with real cuts to exam machining accuracy before cleaning up, packing and shipment.

PACKAGE & SHIPMENT

All SKYFIRE CNC machines will be packed up with standard plywood crates to make sure safe transport.

We also provide CNC programming, client sample test machining sevices to make sure customers can do right job with our machnes.

OPTIONS & TOOLING ACCESSORIES

Please refer to SVM-1 series DATASHEET for more machine options and high quality tooling accessories available. Order together with machine will save a lot for you!

KNOW MORE

More questions please refer to FAQ or directly email us for prompt answers: info@skyfirecnc.com

WARRANTY & SERVICES

We provide 12 month full free quality warranty and life long technology supports. Please review details in:

Warranty & Services document

|